MANUFACTURING DIVISION

Refined "steel knowledge" and "technical capability"

We internally manufacture steel pipes required for the transportation of "water," and steel pipes used for various applications and facilities, such as water supply/wastewater, agriculture/industrial water, and water for electrical power, etc. Our products comply with the JIS and JWWA standards, and strict internal product inspections and high value competitiveness respond to the demands for large-scale overseas plants, not only those in Japan. FUSO is also moving towards the manufacturing of products in fields other than the transportation of water utilizing our pipe manufacturing technology, including water pipe bridges and deformed pipes, and the knowledge of manufacturing water treatment machinery. We continue to challenge new fields, such as evaporation pipes for thermal power and hydroelectric power plants, and small-scale hydropower systems utilizing agricultural water and water supply/wastewater.

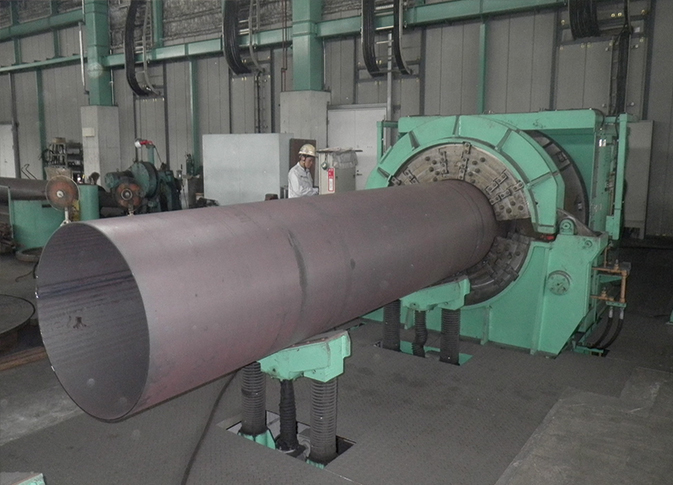

Steel pipe plant

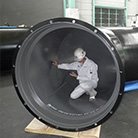

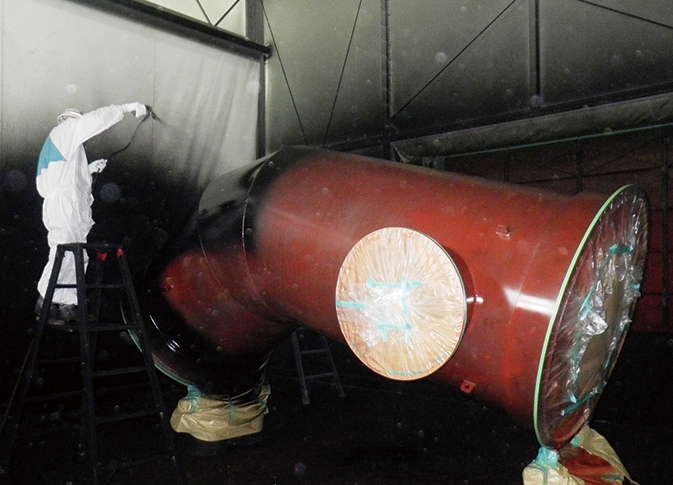

This plant is equipped with the latest large-sized CNC (computer numerical control) vertical turning machine, etc., which enables design and manufacturing of various high quality deformed pipes. Also, in order to ensure quality, the coating plant is equipped with an air supply and exhaust system which changes the air in the entire plant four times per hour, and an air conditioning system that controls the temperature and humidity to an ideal condition.

Plant Overview

- Address

- 796-1 Goto-cho, Takamatsu-shi, Kagawa Prefecture 761-8031

- Total lot area

- 56,287m2

- Plant floor space

- Pipe manufacturing plant 10,434m2

Coating plant 6,770m2 - Pipe manufacturing capability

- Maximum diameter 5,000mm

Manufacturing Plant

"Manufacturing process" by advanced technology and consistent quality control

In order to manufacture steel deformed pipes, advanced pipe manufacturing technology is required, such as the removal of strains based on various causes and strict observation of the specified dimensional tolerances, etc. Therefore, it is necessary for the manufacturer to perform careful control. FUSO's products are manufactured under a consistent quality control system, where various checks are performed in each process, including welding, strain, machining, and dimensions, etc. for the materials with completed full-scale development. Moreover, we provide various coatings according to the requests of the customer, in order to manufacture a "reliable product."

Manufacturing process

1. Cutting

2. Press

3. Roll

4. Automatic welding

5. Pipe cutting

6. Edge preparation

7. Machining

8. Assembly

9. Welding

10. X-ray inspection

11. Under coating

12. Inner surface coating

13. Outer surface coating

14. Coating inspection

15. Completed

1. Cutting

2. Press

3. Roll

4. Automatic welding

5. Pipe cutting

6. Edge preparation

7. Machining

8. Assembly

9. Welding

10. X-ray inspection

11. Under coating

12. Inner surface coating

13. Outer surface coating

14. Coating inspection

15. Completed